Designed in compliance with EHEDG guidelines, certified by Weihenstephan and verified by the highly respected Fraunhofer Institute.

Laska is not merely keeping up with the growing importance of hygienic design for companies in the food industry, it is actively shaping and promoting it. Laska is not the only developer and manufacturer of processing machines based on hygienic design, but they don’t believe anyone else has such a perfectionist and consistent approach to the issue.

The company spares no expense when it comes to setting the highest possible bar for hygienic standards, from redesigning entire machine groups through to comprehensive, multi-day testing and acceptance procedures.

Aiming for perfection means measuring yourself against the most stringent standards and in the toughest testing procedures.

Designed in compliance with EHEDG guidelines

All new machines are developed and designed in compliance with the strict EHEDG guidelines. These guidelines guarantee easy, safe and hygienic cleaning and are becoming increasingly important in the food processing industry, especially in the field of meat processing. To meet the standards, Laska engineers have developed special sealing rings for sealing metal connections, as well as a hygienic casing for scrapers, because none of the existing components met the toughest demands.

A non-detachable screw complying with EHEDG guidelines was recently designed and certified. To achieve this certification, individual components of a machine designed for cleaning with liquids underwent a comprehensive testing and inspection procedure at the Weihenstephan research centre.

Hygienic Design Weihenstephan certified

A further certification from Weihenstephan assesses the level of implementation of hygienic design requirements in an entire installation compliant with EHEDG, the EN 1672-2 standard and the EU Machinery Directive. To be designated as an HDW Hygienic Design Certified System, all components are assessed for their level of compliance at an individual part level. This is a consistent extension of the EHEDG individual component certification. Laska has become the world’s first company to successfully obtain Hygienic Design Weihenstephan certification for a grinder as a complete installation, the WWR 200. The entire machine was inspected on site at component level as part of an exhaustive, multi-day testing and acceptance procedure, full documentation of implementation of the standards was presented and assessed and a comprehensive risk analysis was conducted.

Verified by the Fraunhofer Institute

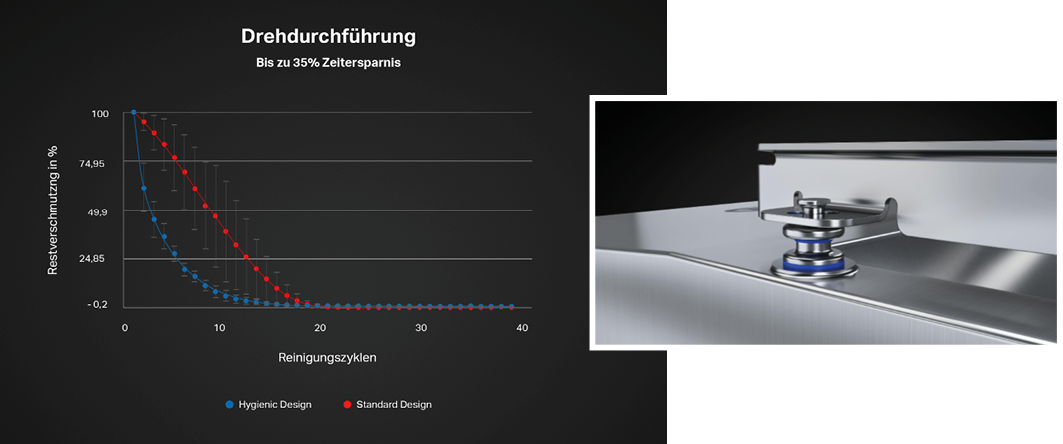

Thanks to Laska’s most recent efforts, they have had their hygienic design components tested by the highly respected Fraunhofer Institute. In a practical test setup, which compared a standard design component with a hygienic design component, Laska demonstrated effective simplification of cleaning and associated resource savings of up to 35.5%. This was accompanied by an impressive residual contamination figure of less than 5%. To perform the test, the components supplied by Laska were sprayed with a specially formulated contamination emulsion, dried for several hours and then cleaned using standard everyday methods. The success of the cleaning process was measured and compared over multiple cycles at key positions such as weld seams, axes, rotation mechanisms and seals.

These and other tests clearly verified the superiority of the hygienic design components.

These certifications and test successes are the supreme mark of recognition for the hygienic design of Laska machines, and the company is delighted that thanks to these prestigious official awards they can offer users even greater assurance.

www.laska.at