How can meat products be packaged in a resource-saving way, without having to compromise on product protection, hygiene and convenience? This is where the packaging industry, food manufacturers and retailers are searching for new solutions, for example for self-service meat products. Until today, it is impossible to do without plastic, but with FlatSkin® there now is an innovative packaging method available that proves to be more sustainable. OSI Europe, subsidiary of the globally active OSI Group that supplies meat products to leading brands in food service and retail, has opted for this novel packaging system for its high-quality steaks. With more than 65 production sites and 20,000 employees in 17 countries, the company has become a pioneer in the introduction of FlatSkin® packaging.

A major trigger for OSI to switch to this new packaging system have been the changing market conditions. As Erik Schöttl, Managing Director Foodworks Europe at OSI, explains: “We recently see a trend towards high-quality products, such as our dry-aged steaks. These products need to be packaged accordingly. At the same time, sustainability has become a key factor in the decision process of the consumer. Therefore, we started looking for a high-end packaging solution for our premium beef steaks from around the world, which would not only combine maximum product safety and high-class optics, but also convenient handling, cost-efficiency and conservation of resources.” The answer was FlatSkin®, a joint development of SEALPAC, supplier of high-tech tray-sealing technology, Van Genechten Packaging, specialist in cardboard packaging and folding cartons, and Wentus Kunststoff GmbH, professional in the field of barrier films and laminates. By joining hands, these three companies were able to develop a skin pack that fulfils the demands expressed by OSI.

Marketable system with many savings

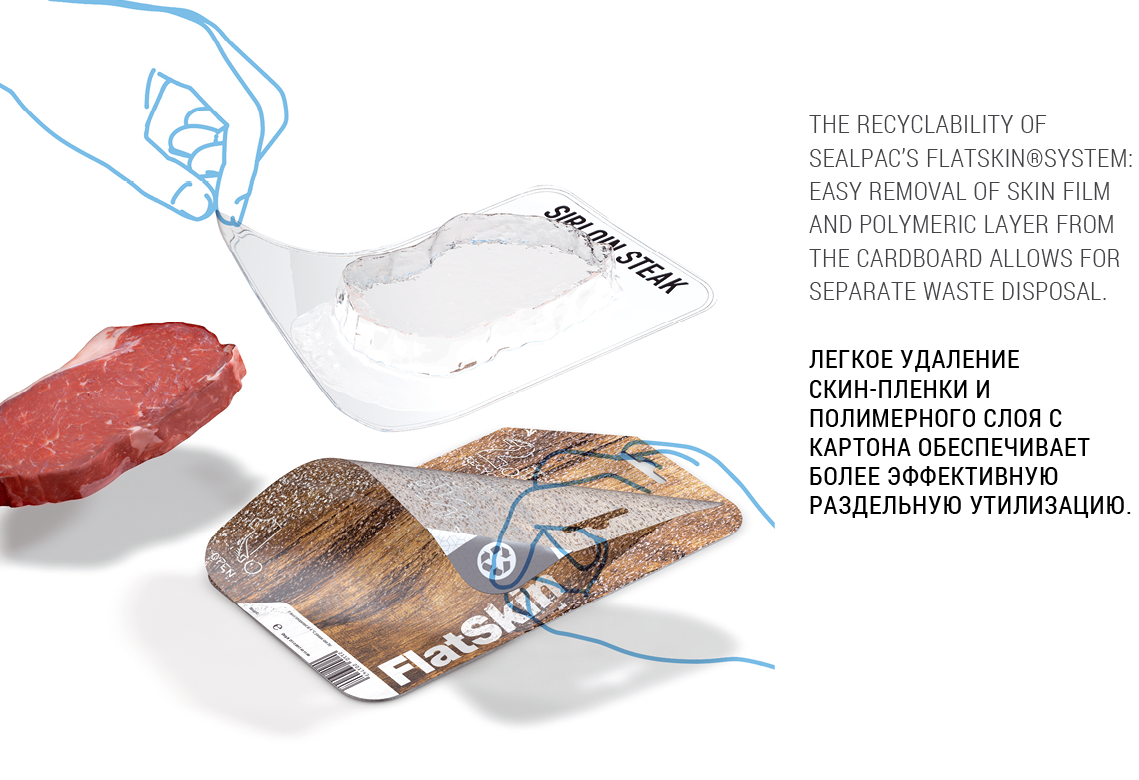

In the FlatSkin® process, a highly transparent barrier skin film fixates the product, for example a steak, directly onto the extremely flat cardboard carrier produced from bleached or unbleached fibre, which has been coated with a polymeric protective layer. This layer provides stability to the cardboard and forms a reliable barrier against grease, moisture and oxygen. The cardboard carrier can be printed on both sides, hence offering optimal space for product information whilst providing unique branding opportunities. The FlatSkin® system combines all the benefits of skin packaging, such as extended shelf life and post-maturation, with a particularly attractive product presentation. At the same time, the system is extremely economical and sustainable, as it significantly reduces the amount of plastic used and improves recyclability.

Burkhard Meyer, Sales Director at Wentus, explains: “With this packaging solution, compared to common plastic skin trays, a plastic reduction of up to 75% can be achieved. The top film, which fixates the product onto the laminated cardboard carrier, has a thickness of just 80 to 150 micron.” Marcel Veenstra, Marketing & Communications Manager at SEALPAC, adds: “The trick to FlatSkin®: after taking out the product, the thin polymeric layer is easily removed from the cardboard by means of a peel tab to allow for separate disposal of the cardboard carrier as paper waste, and both liner and skin film as plastic waste.“

The three participating companies put a great deal of effort into the FlatSkin® project. Challenges included the climatic conditions prevailing in the meat industry, such as the high levels of humidity in production and logistics. “If fibrous materials, such as cardboard, absorb moisture, the fibres start to expand, which can cause the carrier to bend. This is why the carriers need to have excellent flatness. For this reason, we performed numerous tests under cold and humid circumstances in our own laboratory and in SEALPAC’s Experience Centre in Oldenburg, Germany, to ensure a smooth packaging process and excellent optics at all times”, explains Manfred Grupp, Sales Manager at Van Genechten Packaging. By using the optimal peel material, an excellent match of cardboard and skin film is guaranteed, as well as a reliable seal of the packaging. In addition, a large-sized peel tab allows for easy opening of the skin pack.

Positive feedback from retail

The result is convincing: FlatSkin® not only ensures savings in plastic. The excellent two-sided printability of the cardboard carrier, which offers sufficient place for branding and product information, makes the additional sleeve, often required for skin products, unnecessary. “With the new packaging system, the filling rate of the transport boxes is also higher, which in turn reduces the amount of trucks on the road. Furthermore, not only do we use less material for packaging, but by separating and disposing of the components separately, we support better recycling”, says Markus Holler, Group Operations Director Europe at OSI. FlatSkin® is used for the premium products within OSI’s product portfolio. Robert Zeller, Sales Director Meat Solutions at OSI, emphasises: “Most important, our customers receive the highest quality. Meat products, such as our steaks, mature very well in the packaging. After opening, the meat keeps its appetizing colour and convinces with an extremely tender structure.”

OSI Europe is proud for implementing this new packaging concept so quickly and for bringing it to the market first. Since the spring of 2018, the company has been successfully supplying all NETTO Marken-Discount stores in Germany with beef steaks packaged in FlatSkin®. The positive feedback from the retailers underlines the success of FlatSkin®. The responsibles at OSI Europe are particularly pleased about the fact that, despite a completely new packaging process, they received no complaints after many thousands of delivered packs. The company can be regarded as a pioneer for bringing more sustainability to the self-service meat segment, hence creating a strong buzz in the market. Now the use ofFlatSkin® is to be gradually extended to other countries.

Plastic packaging materials – as much as necessary, as little as possible

How will this development continue? All the partners involved in the FlatSkin® project agree that efforts should be made towards an even more efficient use of resources. OSI will continue to focus on more sustainability through better recyclability and further reduction of consumables. “We are investigating the extent to which the thickness of our packaging can be reduced while maintaining the same level of protection for our products”, says Markus Holler.

Film manufacturer Wentus is also working on further reduction of film thicknesses, as well as on recyclable monomaterials, such as PP-based film. “This single-material packaging must be as powerful as common solutions, for example, have a high barrier to survive on the market”, emphasizes Burkhard Meyer. “For fresh food products, due to the required water vapour barrier, oxygen barrier and hermetic seal, there is no real alternative to plastic. That is why we are all challenged to think about sustainability in different ways”, says Marcel Veenstra. Manfred Grupp from Van Genechten Packaging concludes: “With FlatSkin®, we have impressively shown that it is indeed possible to replace parts of the plastic packaging with other materials, such as fibre.”