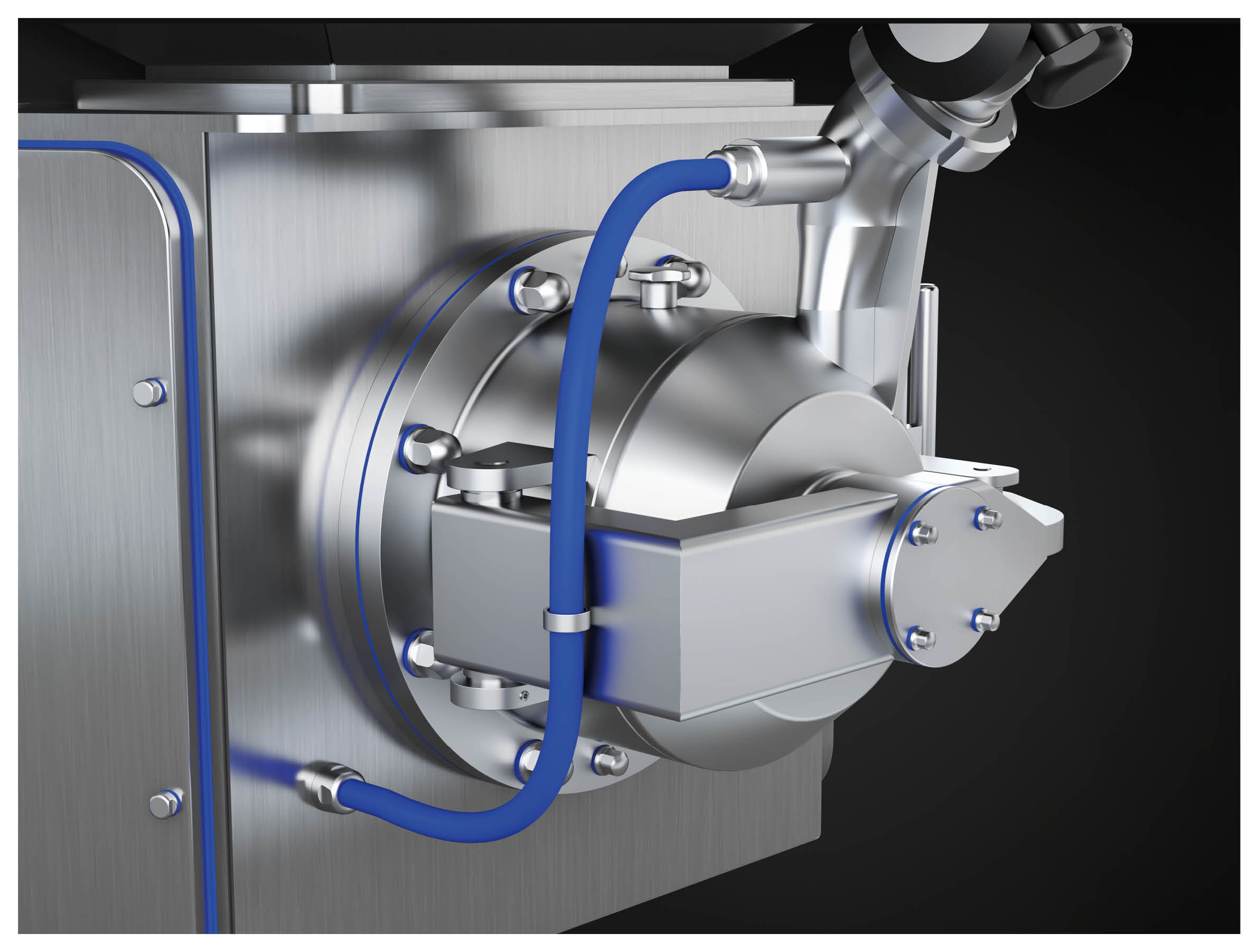

Another new product was introduced at IFFA 2022: the FZ 225-H ultra-fine emulsifier. It represents the finest emulsions, the highest output and, at the same time, the easiest operation and lowest maintenance requirements. Here is an overview of all the advantages of this highly innovative tool.

The perfect result. Less wear and tear.

Cutting performance and degree of fineness are decisive for fine shredding. With its streamlined material flow and up to three-stage cutting system, the FZ 225-H guarantees a superior result – in terms of both output and quality. As it is possible to produce even the finest emulsions thanks to the perfected geometry of the cutting set, this ultra-fine shredder can cover a wide range of applications.

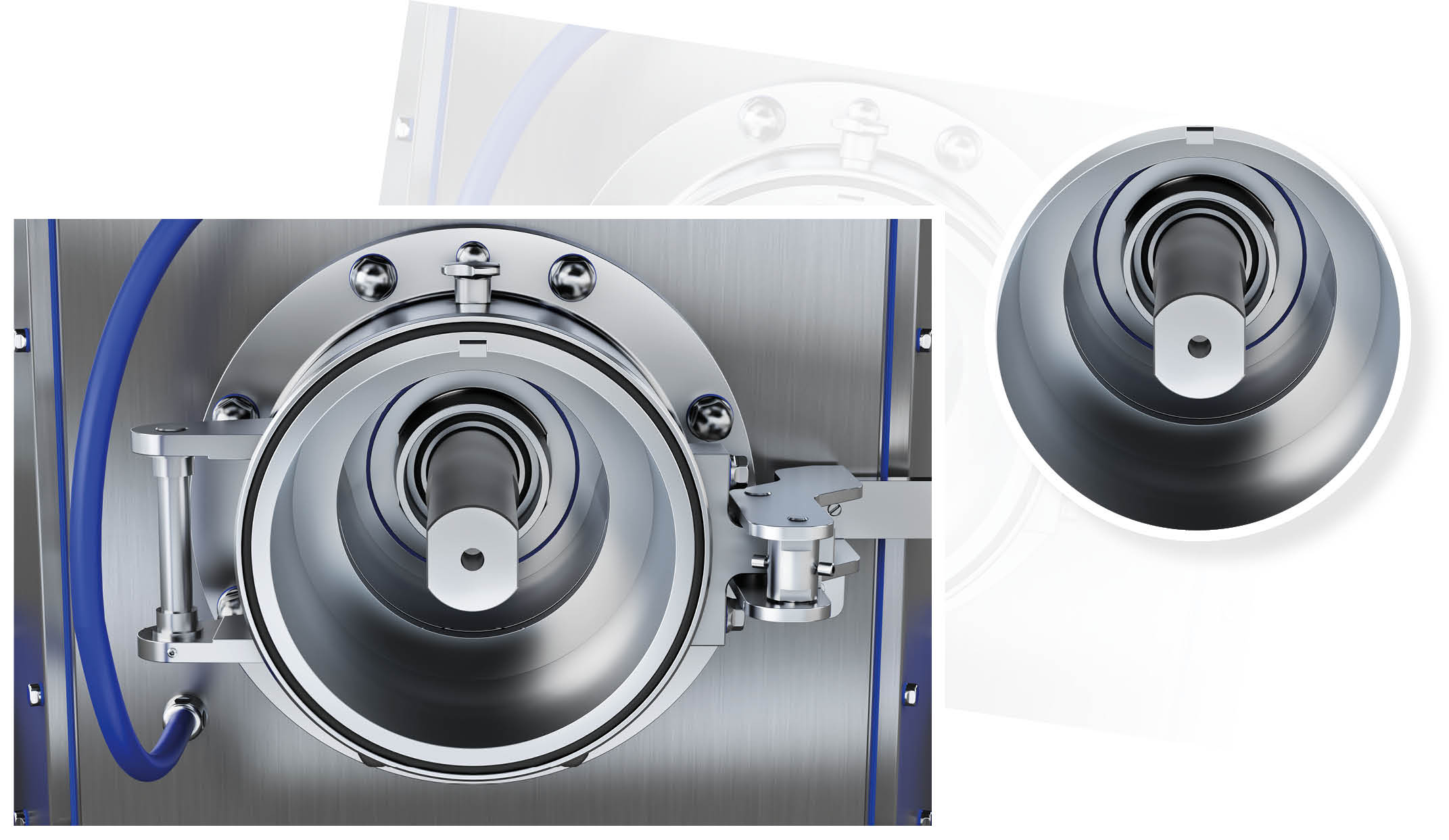

To counteract the particular demands of fine cuts and tight fits, the FZ 225-H has a patented electro-hydraulic adjustment of the distance between the blade and the perforated disc. In this way, it is always within the optimal range. This reduces wear and tear costs on the cutting unit by up to 50% and ensures that product results are always the same. The self-adjusting blade set cover with spherical bearing also reduces wear and tear. It automatically aligns itself with the blade set whenever it is closed.

Less cleaning effort. Thanks to Hygienic Design.

Costs are also an important factor in cleaning. The more efficient, simpler and faster the cleaning process is, the less effort it requires. Therefore, all the key components of the FZ 225-H follow the Hygienic Design approach: maximum cleanliness at minimum cleaning time. The ultra-fine emulsifier as a whole is also protected against moisture and contamination of all kinds. This bundle of Hygienic Design measures thus ensures a combination of the highest product quality and high cost-effectiveness.

Apart from this, an abrasion-free cleaning mode ensures a wear-free cleaning process.

Easy to operate. Easy to maintain. All good.

A variety of details make working with the FZ 225-H very easy and economical as well. The machine shuts itself off when it is idle. This benefits durability. The knife blades are interchangeable, which saves costs. Maintenance access has also been optimised, which makes servicing easier and thus reduces downtime. Thanks to the fact that it has large rollers, the FZ 225-H can be moved with little effort.

As the LASKA operating system is standardised, little training is required – operating errors are almost impossible. Production data is constantly recorded, which enables seamless traceability of processes.

www.laska.at