For Möllers, a butcher and wholesale grocer in Cologne, Germany, keeping up with shifting trends has been key to its success for over 70 years. When it came time to update the company’s portion cutting technology, the new TREIF HAWK portion cutter quickly proved its worth, significantly enhancing the speed, ergonomics and flexibility of the process. We had the opportunity to speak with Helmut Schmid, Production Manager, and Karl Steger, Deputy Production Manager at Möllers, to gain insights into their experience with the TREIF HAWK.

Strength in embracing innovation

Founded in 1950 by Bernard Möller, the butcher offers an extensive range of meats and delicatessen specialities. Möllers takes pride in its high-quality products and its proactive approach to keeping pace with culinary trends and evolving market challenges. This proved particularly advantageous when the pandemic hit, severely impacting the gastronomy and retail sectors, leading Möllers to adapt rapidly to new ways of working.

In line with this ethos of embracing innovative technology, when the time came to update their portion cutting technology, they approached TREIF, now a part of Marel, to explore the latest options and advancements.

Seeking flexibility, agility and consistency

Möllers sought a portion cutting solution capable of processing a broad range of meat products, including beef rump steak, pork loin, veal top, hip, beef tenderloin, pork medallions, pork loin, pork chops and neck bone-in and boneless. This diverse product lineup called for a highly versatile portion cutter.

Given that Möllers’ customers can place orders up until the evening, the cutter also needed to be exceptionally agile and capable of swiftly responding to changing customer demands. Möllers was keen to boost speed, efficiency and product quality. As Schmid and Steger note, “With our current [portion cutting] solution, we often have problems if the products are not all at the same temperature.”

Working in partnership to trial the TREIF HAWK

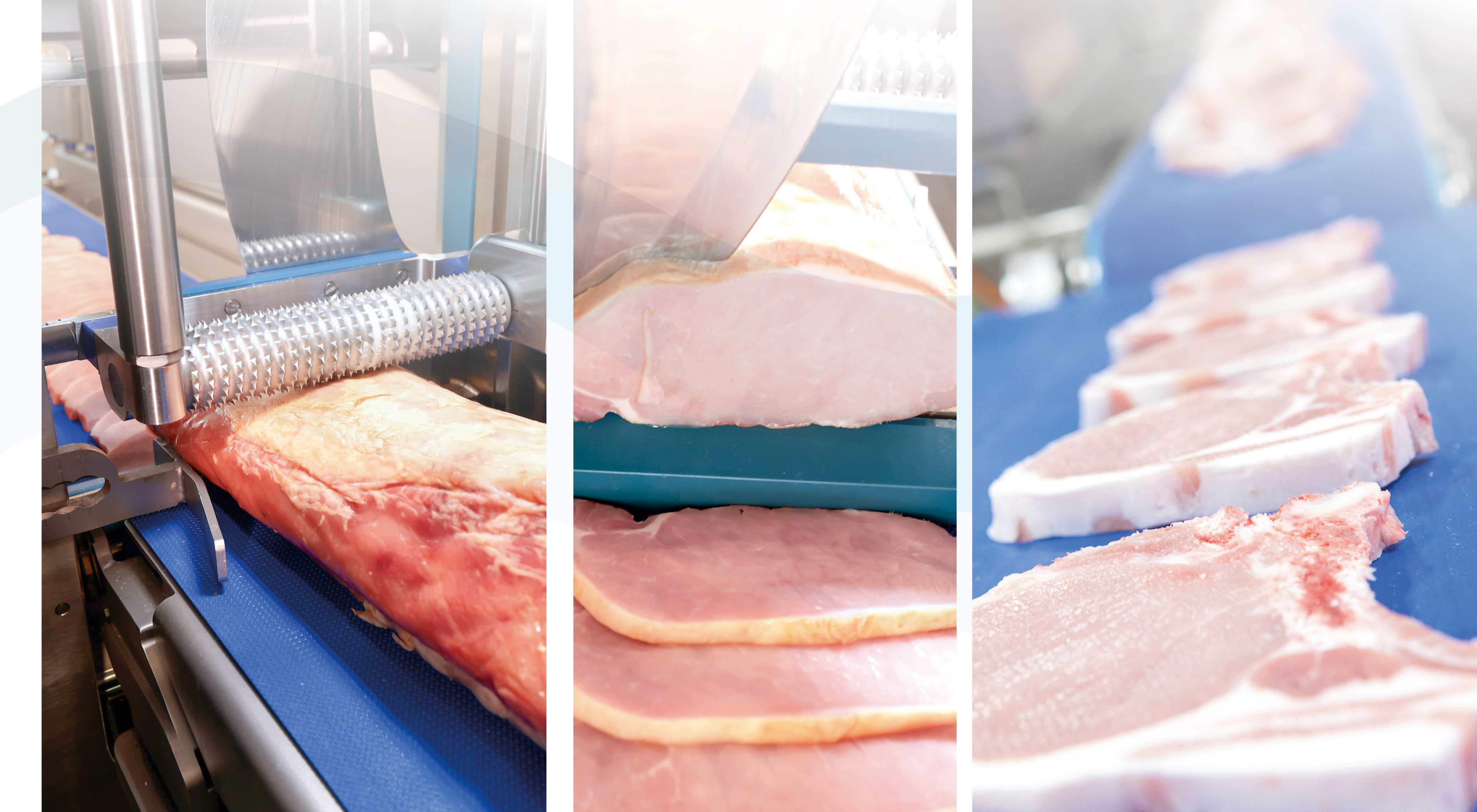

Marel gave Möllers the opportunity to trial the TREIF HAWK, the newest member of the highly successful family of TREIF portion cutters. Designed as a transformative solution for butcheries seeking to scale up their operations, it was an apt fit for Möllers’ requirements. Offering exceptional accuracy and versatility, it’s the only machine in its price segment that can cut bone-in meat by weight.

Testing the TREIF HAWK at Möllers’ site gave the team a firsthand feel of how it would fit into their production line. At the same time, these real-world customer trials offer Marel and TREIF vital feedback, enabling fine-tuning to meet customers’ exact needs.

This type of partnership is a real win-win. As Schmid and Steger explain, the process was “very positive. Everything was well explained, and quick actions were taken whenever there was room for improvement.” There was excellent co-operation between Marel and Möllers, and everyone benefited from the opportunity to give direct feedback and adjust the machine accordingly.

Boosting speed, consistency and adaptability

Since integrating the TREIF HAWK into their operations, Möllers has seen substantial enhancements. “We are at least twice as fast with the TREIF HAWK!” say Schmid and Steger. With the capacity to cut up to 360 slices per minute, the TREIF HAWK delivers the superior speed, efficiency and yield needed to adapt to new market opportunities. At the same time, its intelligent scanning system extracts maximum value from raw materials and enhancing profitability while minimizing waste.

The TREIF HAWK has also effectively addressed Möllers’ concern about inconsistent results due to varying raw material temperatures. It easily handles a wide range of raw materials, whether fresh, crust-frozen, tempered, boneless or bone-in, producing precise, visually appealing portions without the need for crust freezing. However, raw materials can still be crust-frozen if desired.

Möllers is very pleased with the improvements, with Schmid and Steger noting, “Even if the products have different temperatures, the results are always good. For example, we cut pork loin with and without crust-freezing, and it’s always equally good.”

The TREIF HAWK requires only minor adjustments to transition between product types, making it simple to adapt quickly and seamlessly to evolving customer demands. “We can react at short notice without big changes on the equipment,” explain Schmid and Steger.

Automated loading transforms efficiency and labor dependency

The TREIF HAWK‘s optional automated loading feature has proven to be a game-changer for Möllers. “We are happy with the automatic loading as it allows us to save an enormous amount of time. The machine grips the product automatically without us having to do it manually,” say Schmid and Steger.

This innovative feature allows for efficient product handling, freeing up staff for other tasks. “We can now deploy the staff differently for downstream processes and, for example, working at the flattener or have the cut products packed away.”

Elevating hygiene and user-friendly design

The TREIF HAWK facilitates effortless cleaning. Its robust metal construction and accessible design ensure the highest hygiene standards and product safety. “Everything is made of high-quality stainless steel. We don’t need to worry about plastic becoming brittle and contaminating our products as a result of the cleaning processes,” explain Schmid and Steger.

The managers also applauded design elements such as the down-holder that securely holds the raw material in place. “There are no issues with chops; it doesn’t jump during the cutting process,” they explain. Additionally, the machine features a pause button at both ends, enabling operations to be paused, for example, to switch out a box, without the need for a stop button to open the machine.

Looking ahead with confidence

With the TREIF HAWK’s adaptability, precision and efficiency, Möllers is set to continue its journey of growth, keeping pace with industry trends and customer demands. Their story is a testament to the power of technology to constantly adapt and seize new opportunities.

www.marel.com