Meyn developed innovative solutions to speed up poultry processing to 15,000 bph

Rising consumer demand for high-protein food and changing customer preferences have spurred the global market for poultry meat. In response to this growing demand, the market has been forced to increase production volumes. This results in longer production days and increased line speeds. Especially greenfield projects, but also existing plants demand the highest possible processing capacity within the available space and time. It goes without saying that increased volumes should not affect the high standards of product quality and animal welfare.

Meyn, the market leader in poultry processing, is well known for its reliable equipment with high yields at already high processing speeds. In response to the growing demand for even higher line speeds, Meyn has upgraded its machines with innovative solutions to process broilers quicker, achieving high levels of quality and maximize yield. So, Meyn is very proud that this year alone, machines for at least three new 15,000 bph high-speed processing plants will be delivered.

Complete overhaul on evisceration machines.

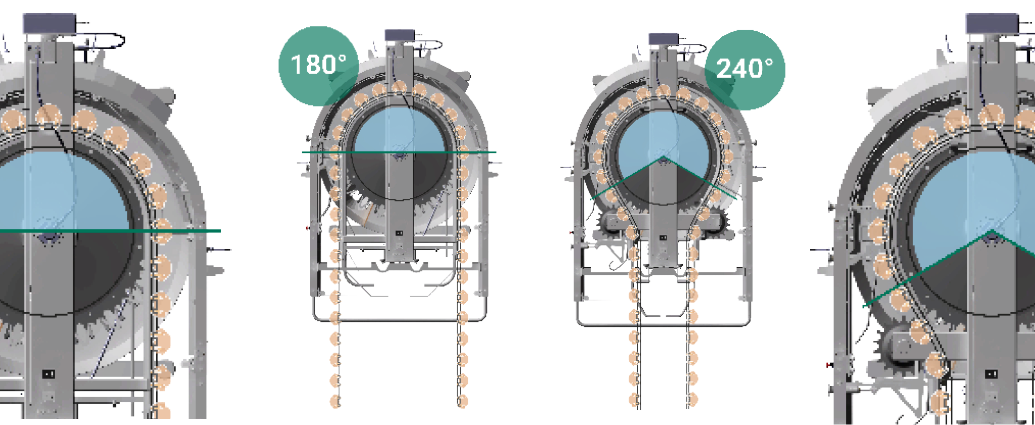

Just increasing line speeds is not enough, for Meyn: creative solutions that focus on maximizing revenue over the complete production chain are essential. That’s why new versions of existing evisceration equipment are implemented with 20 units in a 240o frame (instead of the normal 180 degrees), allowing for longer processing contact time in each machine. The new 240o machine design matches high speeds with superior product quality and maximum food safety.

“Customers are looking to increase their production speed whilst also reducing waste and quality defects. The new 240o frame enables us to meet customer expectations and help them to achieve further efficiencies,” said Pete van Poorten, Product Manager Meyn. “Many of our installed systems have already been running above 13,500 bph, and this is the logical next step.”

Easy maintenance at 15,000 bph

Furthermore, higher line-speeds mean more processing activities per hour. In theory, this would result in shorter interval times between the sharpening or even replacement of knives. Meyn has further improved the durability and quality of all cutting blades to reduce maintenance and maximize uptime. Moreover, in some modules the blades have changed from smooth to serrated cutting edges, resulting in an up to four times longer durability.

Other innovations by Meyn to run a processing line at 15,000 bph are the new Meyn Carousel rehanger M2.0 and the new Meyn Line weigher M2.0. For processing after chilling the Meyn Physic and Flex M3.0 cut up lines are updated to match the 15,000 high-speed lines with exactly two cut up lines.