Polish company Starmeat invests in leading-edge meat separation systems AM2C Beluga and Barracuda from Provisur Technologies

Starmeat, headquartered in Koluszki, Poland, is one of the most modern poultry processing plants in the world. Thanks to the use of sophisticated production equipment and rigorous quality control, the company serves a global network of customers. The state-of-the-art production facility and the exceptional quality of Starmeat products are made possible by the company’s partnership with Provisur Technologies, a pioneering food processing equipment manufacturer headquartered in Chicago, USA. Since integrating Provisur’s AM2C Beluga and Barracuda separation systems into its processing lines, Starmeat has gone from strength to strength, increasing yield and maximizing quality.

Based in Poland – worldwide market

Starmeat was founded in 2010 and has specialized in the production of poultry meat since 2013. In 2018 the company began looking for design solutions and technological innovations for a new meat processing plant. This quickly led to a collaboration with Provisur Technologies in the knowledge that Provisur equipment would offer the necessary combination of innovation, high performance and exceptional hygiene. Construction began in 2019 on what is to date the most advanced minced meat and meat-cutting production facility in Poland. At the end of 2020 production commenced, enabling Starmeat to produce 200 tonnes of high-quality meat per day.

Known for their outstanding quality, Starmeat deliver their products to domestic and international meat processing plants as well as international meat trading companies. These channels are responsible for over 80% of the volume sold. The remaining 20% are customers in the pet food industry as well as poultry meat commercial companies. Mechanically separated poultry makes up the largest share of production for sausages, pates, nuggets, kebabs and delicatessen products.

A collaboration built on excellence

When Starmeat began to think about constructing a new production plant, the company was dealing with two challenges:

The first of these is the ongoing dynamic development of the poultry sector. As the only segment of the meat industry with increasing consumption, poultry meat production has an average annual growth rate of 7%. Any new equipment would have to keep pace with these developments and allow Starmeat to meet the increase in demand.

Secondly, maintaining quality and safety despite the increase in production is of paramount importance to a company whose motto is: “Quality is our advantage.” Starmeat uses only the highest quality domestic poultry which then undergoes a series of checks at all stages of its production. Ideally, the new production equipment should not only preserve this level of excellence but raise it even further.

When designing the new plant, it was therefore clear that only the most modern meat processing systems, metal detectors and meat analysers would do the job. Additionally, it would be necessary to constantly monitor parameters such as water, fat, protein and calcium whilst maintaining speed, maximum yield and flexibility.

Provisur became Starmeat’s partner of choice due to its global reputation as one of the most innovative meat separation systems manufacturers in the world. Based on years of experience, as well as technological excellence, the solutions offered by Provisur focus on those requirements that are crucial to Starmeat.

Advanced technology: reliable, safe, easy to use

It was therefore decided that Provisur’s Beluga and Barracuda meat separation systems would be integrated into the Starmeat production lines.

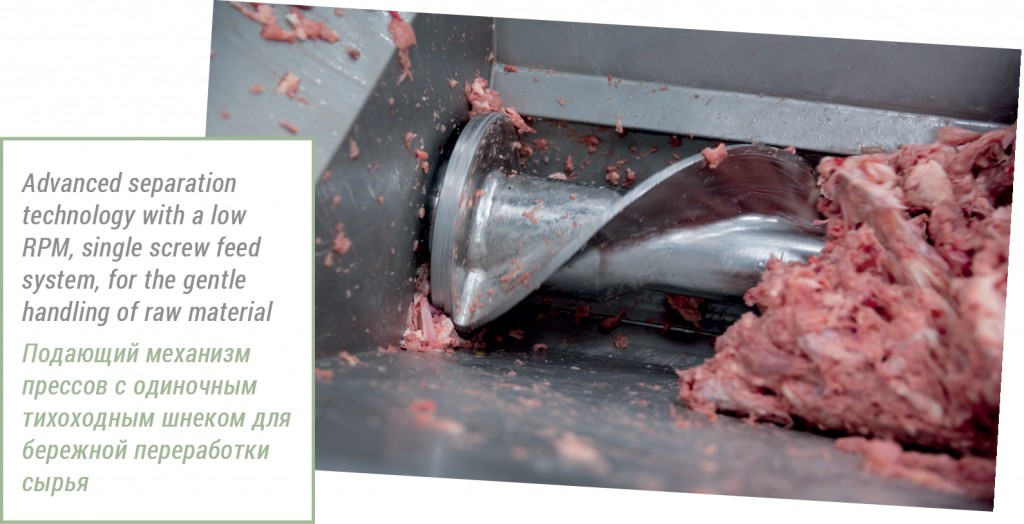

The Beluga system offers the best deboning and desinewing technology currently on the market and provides a comprehensive solution to the demands of the Starmeat production line. It protects the raw material through a gentle, minimal temperature rise. It provides important product consistency, high-quality textures and low calcium levels of less than 1000 ppm.

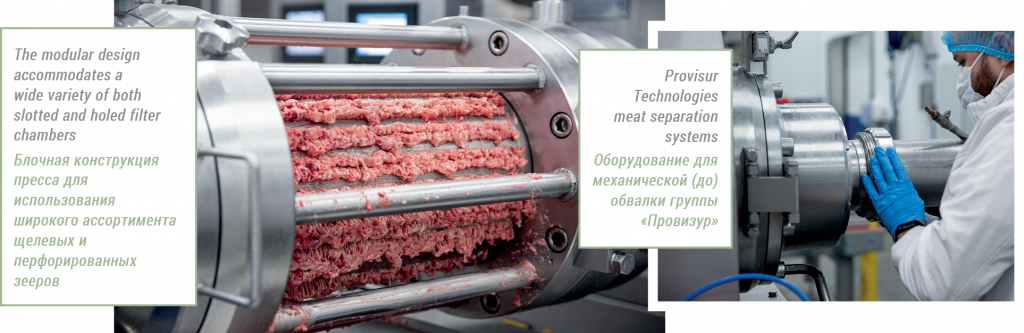

With the Barracuda system, Provisur has created a new standard in meat separating technology. It is a modular system that offers almost unlimited configuration flexibility to accommodate specific applications. The high-pressure system works with a vane pump which is designed to pump bone waste, mechanically separate meat, and products that are fluid in nature.

Both systems are simple to use and easy to clean and maintain, resulting in advanced food safety and hygiene. Importantly for Starmeat, the systems’ inbuilt flexibility means they are also easy to integrate into existing production lines. Furthermore, both systems offer simple and smooth adjustments when future changes become necessary.

Window to the future: quality meets sustainability

For a company like Starmeat, the greatest benefit of working with Provisur systems has been the improvement in product quality. Another advantage offered by Provisur is superior customer service and fast reaction times. When emergencies arise Starmeat has been able to call on Provisur offices in Poland and France to provide reliable and speedy support.

As a result of their first successful collaboration, Starmeat is already thinking about further investments. “Despite the fact that only a year has passed since we launched one of the most modern poultry processing plants in the world, we are already thinking about the future,” says Daniel Katowicz, CEO of Starmeat. “We are developing another range of products and look forward to creating it in tandem with the expertise and experience of the Provisur team.”

The Polish poultry sector is growing stronger all the time. Both this and the EU Green Deal development strategy will have a very significant impact on Starmeat’s future business. Daniel Katowicz explains: “This means that together with Provisur we will also look closely at finding new, innovative production solutions based on environmental sustainability.”