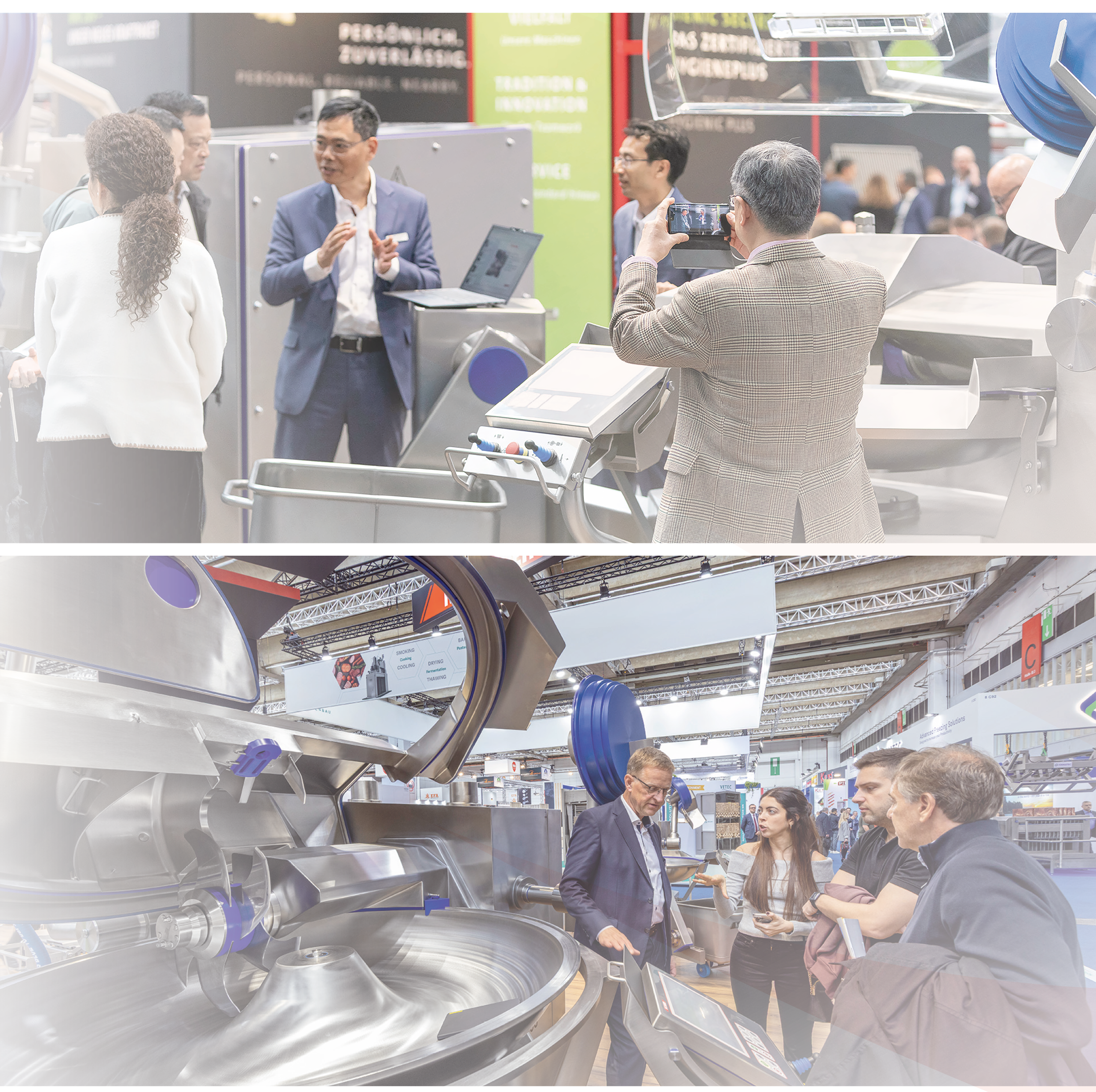

Sophisticated cutter and grinder technology for food processing, a comprehensive overview of K+G Wetter machines for trade and industry, and last but not least, the expert and hospitable team: these were the best ingredients for a well-attended stand on all six days of the IFFA trade fair and an extremely positive outcome.

“Numerous intensive discussions and personal encounters with customers from trade and industry made the IFFA a success for us. We were also delighted to welcome many trade visitors from Asia and South America,” summarizes K+G Wetter Managing Director Andreas Wetter. ”The intense demand confirms the great need for our solutions – especially for the new MWW 200 mixer angle grinder, which attracted a lot of interest with its combination of high mixing performance and compact design.”

Work better every day: with the MWW 200 mixer angle grinder

The MWW 200 mixer angle grinder offers everything that makes daily work in food production better: high batch capacity, a footprint of just under 4 square meters without loading, thorough mixing without tunnel formation or spice pockets, and, last but not least, intuitive and safe operation.

“With the MWW 200, we paid particular attention to practical requirements – easy handling, quick cleaning, and reliable results were our main focus,” explains Volker Lauber, Managing Director at K+G Wetter.

“The first of the machines is already about to be delivered. Our customers were particularly impressed by the large mixing volume of 400 kilograms,” says Andreas Wetter, commenting on the impressive performance and efficiency of the extremely versatile grinder.

Read more about the MWW 200 here: kgwetter.de/news-detail

Particularly efficient and hygienic: the cutters from K+G Wetter

The industrial and craft cutters with Hygienic Secure features were also surrounded by visitors and the subject of interested technical discussions. K+G Wetter pays particular attention to a design that optimizes sensitive sealing areas in terms of hygiene: the patented knife cover strip, for example, can be removed and replaced in a single step. In the vacuum cutters, the ingenious design makes a seal between the vacuum chamber and the cutter bowl completely unnecessary. Hand-polished surfaces, large cleaning flaps, and generous ground clearance further simplify cleaning.

The open cooking cutters like the CM 360 enable the production of cooked sausage even without a vacuum function. This feature also attracted great interest from IFFA visitors from all over the world. “For manufacturers whose products do not necessarily require complex vacuum technology, K+G Wetter offers an economically attractive alternative in the form of the open cooking cutters from the Hygienic Secure series,” explains K+G Wetter regional sales manager Ralf Klein. The cooking equipment also saves time and money in daily operation thanks to its particularly energy-efficient design: the cutter bowls are heated and cooled directly via the space in the double-walled bowl.

www.kgwetter.de