In this interview, Günter Breitbach, Sales representative and meat technologist at JBT Schröder, describes the advantages of the new IMAX420 ECO line injector and gives tips for cooked cured products.

Sales representative and meat technologist at JBT Schröder

What should butchers pay particular attention to in terms of production technology when making cooked cured products in general?

Precise dosing and even distribution of the brine in the meat is a basic requirement for a consistently high level of quality for artisan meat products. It all starts with the brine preparation. Only when all ingredients are completely dissolved can they be introduced into the meat via the brine and quality fluctuations can be ruled out. The second important factor is cooling, as the best results are achieved with cold brine in the further process. Brimax brine mixers from Schröder Maschinenbau are suitable for this purpose. Effective filtration of the brine to prevent needle clogging is also important for consistent results. Here we offer graduated solutions with the brine tanks FT130 or UWF250 with filtering.

What else makes high-quality cooked cured products?

The right choice of raw materials is the first step. Meat for cooked cured products should not be brought into the manufacturing process until three days after slaughter. If a pH meter is available, it should be used to check the required cuts of meat: A pH of 5.6 to 5.8 is considered ideal here. The cut and selection of the meat pieces depend on the end product. The different structure of the meat cuts should not be forgotten. Sorting by hard and soft muscles and adjusting the injection parameters also helps to achieve better results. And importantly: temperature control = cold brine, i.e. keep the meat well chilled and the temperatures cold when massaging. Schröder Max massagers have a cooling jacket and thus transfer the cold directly to the product. This results in a homogeneous protein breakdown, which is reflected in a very good cooking yield and best slice cohesion when slicing.

With IMAX ECO line, you have expanded your portfolio of injectors. Why should a butcher company choose it?

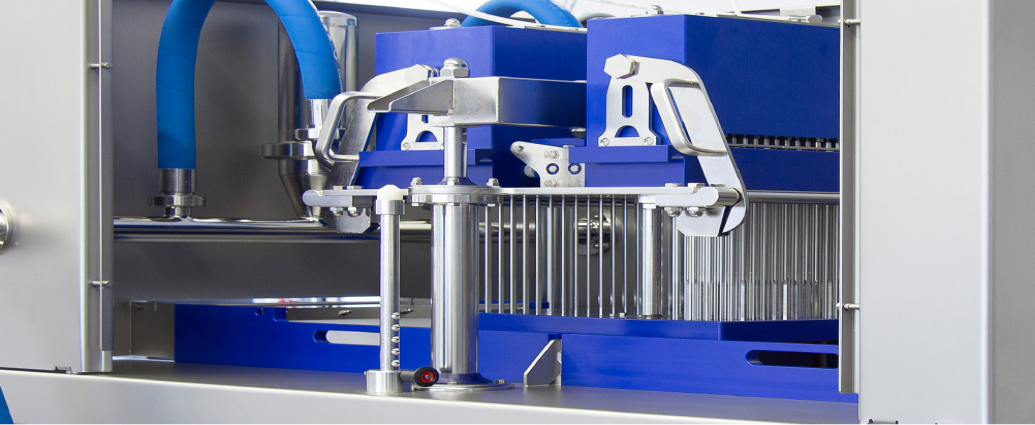

Everything is evolving. Machines today should be easy to operate and clean. They should also be compact and space-saving and require as little maintenance as possible. We have taken seriously customer requests from the trade and medium-sized businesses and implemented them with the new IMAX 420 ECO line. Mechanical solutions are used wherever possible. Electronics are only used where they are necessary and useful. The result is a machine that is perfectly tailored to the daily requirements of this clientele. The operating functions can be selected intuitively. To make work easier, a cleaning function is standard, as in all IMAX injectors. All the equipment options, which are selected in consultation with the customer, make this machine a “reliable colleague” after only a short time.

What technological details of this injector bring real added value?

The maintenance of the IMAX420 ECOline is extremely low, as there are no complex electronics and the complexity of the technology has been kept as low as possible. Hygiene and access to parts in contact with the brine are often underestimated in injectors. Here, lake-carrying pipes or hoses outside the machine frame are easy to clean. Everything to do with electrics is located inside the machine, protected from moisture, in an easily accessible, swing-out cabinet. From a technological point of view, the injector can be equipped with tenderizing needles if required. In this way, brine distribution and protein digestion can be additionally improved and the massage time shortened. If technologically necessary, a stitch pattern with a greater needle density can be selected. 100 needles are standard, 141 needles are available as an option.