With “Hygienic Secure”, the mechanical engineering specialists at K+G Wetter have also completely redeveloped the industrial models VCM 200 L, VCM 360 L and VCM 550 L from the proven vacuum bowl cutter series. The industrial bowl cutter series was awarded the silver International FoodTech Award 2021 at the beginning of the year. With this award, the German Agricultural Society DLG as the organisation of the German agricultural and food industry has been honouring groundbreaking developments in the field of food technology for many years. An international jury of experts awards prizes to the most innovative concepts.

Without seals and tools – Hygienic Secure as new standard

A special advantage of the Hygienic Secure machine generation: the area between the cutter bowl and the vacuum chamber does not need a seal. This eliminates one of the most difficult parts of the hygienically sensitive machine area to clean. Time and costs for replacing seals are also eliminated. In addition, there are large cleaning flaps in the vacuum chamber that can be opened without tools. They allow easy access with the cleaning lance. This way, cleanliness can be checked quickly, safely and reliably. This guarantees hygiene and product safety.

Parts such as the bowl scraper or the bowl support pad can be removed without tools for cleaning and reinserted for the next processing operation. The machine can be loaded and unloaded more quickly thanks to the new, split vacuum lid. These two features save time with each new product and ensure even greater hygiene in the production of high-quality food.

The meat processing specialists at K+G Wetter generally make sure that the vacuum bowl cutters can be cleaned as quickly and reliably as possible in a hygienically safe and thorough manner. Hand-polished sloping stainless steel surfaces, for example, ensure that cleaning agents and water run off safely and reliably without forming puddles or standing water.

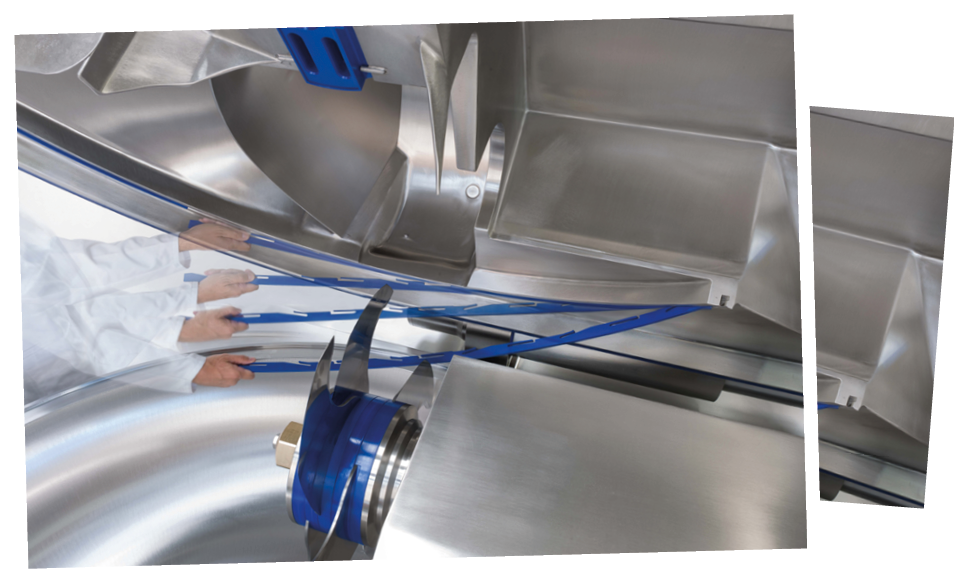

Patent for knife cover strips: safe cleaning, perfect sealing, little wear and tear

A highlight of the vacuum bowl cutters in the K+G Wetter range: the knife cover strip can be removed for cleaning in no time at all. It is also just as easy to snap this seal into place securely without tools thanks to its ingenious shape. One small detail with a big effect: cleaning is effortless and there are no concealed corners where deposits could form. It is easy to visually check the success of cleaning. Contamination of the product through product residues is prevented and pathogenic germs are deprived of a breeding ground.

At the same time, the vertical mobility of the knife cover strip ensures there is no braking effect between the knife cover and the cutter bowl, which of course also greatly reduces abrasion and wear – with perfect sealing at the same time. The new knife cover strip, which at first glance appears to be an unremarkable solution, enables this sensitive area of the machine to be cleaned in a hygienically safe manner. An enormous advantage for product safety. This innovation from K+G Wetter is patent-protected.

Future-proof machine investment for the meat industry

Like all machines from K+G Wetter, the vacuum bowl cutters VCM 200 L, VCM 360 L and VCM 550 L offer a future-proof investment: designed for decades of use, they have always been robust and can be used flexibly for a wide range of products. The cast iron body makes the machines extremely stable and ensures smooth running and durability.

The vacuum technology of the bowl cutters is tried and tested. Because the oxygen is extracted, oxidation during the cutting process is largely prevented. Under vacuum conditions the volume of the meat cells expands, which promotes fast and effective fine cutting. Air pockets in the sausage meat – together with the associated discolouration of the finished product – are a thing of the past. Jelly creation is minimised. The finished product is pleasantly firm in bite, looks appetizing and has an even longer shelf-life. The production advantages of vacuum technology extend into the sales process.

Energy-saving and hygienic cooking function

The vacuum bowl cutters from K+G Wetter are also available with a cooking function. The cutter bowl with double wall guarantees a completely closed system in which the sausage meat does not come into contact with steam or water during cooking and cooling. Another plus: high energy efficiency due to extremely fast heating. The steam consumption is reduced by approx. 30% due to the double-wall construction of the cutter bowl.